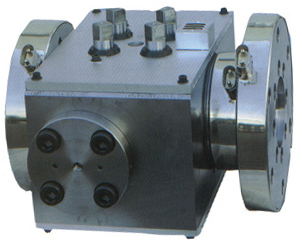

Screen Changer is adaptable to all extrusion likes (Rafia Plant, Film Plant, Monofilament Plant, Sheet Plant etc.) where non stop production is essential. Screen changer is particularly suitable to Thermo Plastic materials such as PE / PP / PS / ABS / PET can be used, suitable to temperature up to 300 C with hourly output is up to 500 kgs.

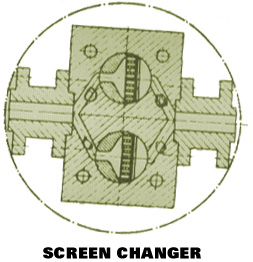

During operation the material is divided into two melt streams flowing through two channels inside the Screen Changer housing. In order to change the filter medium a part of one screen bearing piston including the filter is moved out of the screen changer housing by means of a hydraulics or manual systems. Mean while the part of the screen-bearing piston has remained inside the housing, shuts off the flow channel & thus, production continues through the second filter of the other screen bearing piston which has not left its operating position.